Material Propeties:

usually does not need to be solution heat treated after welding and has vastly improved fabricability, excellent resistance to localized corrosion and to both oxidizing and reducing media. Resists formation of grain-boundary precipitates and is therefore suitable for chemical process applications in the as-welded condition. C-276 has excellent resistance to strong oxidizers like ferric and cupric chlorides, hot contaminated media (organic and inorganic), chlorine, formic and acetic acids, acetic anhydride, seawater, brine solutions, sulfur compounds, wet chlorine gas, hypochlorite and chlorine dioxide.

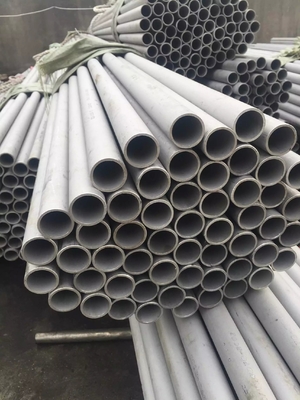

Description & Name: Hastelloy C276 seamless pipe/tube UNS N10276 Nickel alloy seamless pipe ASTM B622

Standard: ASTM/ASME B/SB 622

Material: Hastelloy C276 ( UNS N10276 ), Hastelloy B-2 (UNS N10665),Inconel 600,625,617,690,693, Monel 400, Monel K500,Incoloy800/800H/800HT,825, Alloy20,Alloy28,AL6XN,N08028 etc.

| UNS N10276 Chemical Composition wt% |

| Alloy Designation |

Element |

C |

Ni |

Cr |

Mn |

Fe |

Si |

Co |

P |

S |

Mo |

V |

W |

| HASTELLOY C276 |

Min. % |

- |

REMAINDER |

14.5 |

- |

4 |

- |

- |

- |

- |

15 |

- |

3 |

| Max. % |

0.01 |

REMAINDER |

16.5 |

1 |

7 |

0.08 |

2.5 |

0.04 |

0.03 |

17 |

0.35 |

4.5 |

| Mechanical Propeties |

Hastelloy C276 |

| Density: |

8.9 g/cm3 |

| Melting Point: |

1325-1370°c |

| Tensile Strength Min.(Mpa): |

690 |

Yield Strength Min. (MPa):

0.2% offset |

283 |

| Elongation A 5%(min.): |

40 |

Nominal Dia: 1/2 "to 10" NB for seamless pipe

Schedules: 5S, 10S, 40S, 80S, 10, 20, 30...120, 140, 160, XXS

All dimensions are in accordance with ANSI B36.19 and ANSI B36.10

Size Range for tubing: OD:1/4" (6.25mm) to 8" (203mm), WT 0.02" (0.5mm) to 0.5"(12mm)

Length:

30 m(Max) or as your requirement

Process:

Cold drawn, Cold rolled, Precision Rolled for Seamless Pipe or Tube

Finish: Annealed & pickled, bright annealing, polished

Ends: Beveled or plain end, square cut, burr free ,Plastic Cap at Both end

Packing: Bare packing/bundle packing with woven bag/wooden or steel frame crate packing/plastic cap protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Inspection and Test Procedure

| 1.100% PMI,Spectro Chemical Aanlysis Test for Raw Material |

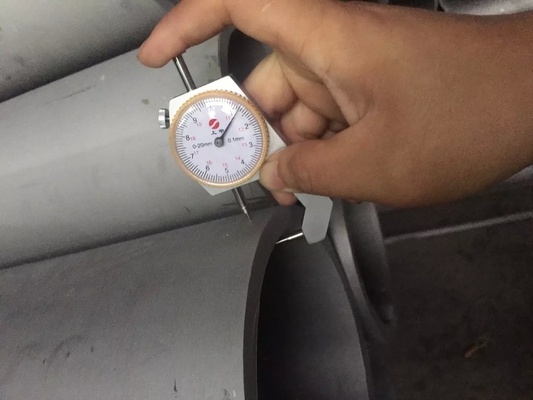

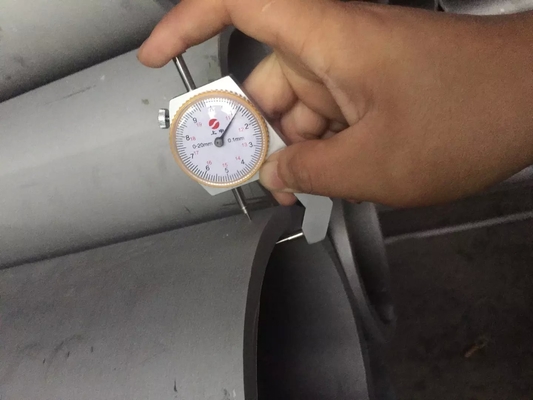

| 2.100% Dimension & Visual Examination |

| 3. Mechanical Properties Test Include Tension Test,Flaring Test (For Seamless tube/pipe)/ Flange Test (For Welded Pipe & Tube), Hardness Test ,Reversed Flattening Test |

| 4.100% Hydrostatic Test or 100% NON-DESTRUCTIVE Test (ET or UT) |

| 5.Radiographic Test for Welded Pipe (shall be accordance with specification,or shall be as agreed upon between the purchaser and vendor) |

| 6.Straightness Test (optional) |

| 7.Roughness Test (optional) |

| 8.Intergranular Corrosion Test(optional) |

| 9.Impact Test (optional) |

| 10.Grain Size Determinations (optional) |

| NOTES : ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!