Hot Rolled Duplex Stainless Steel Plate S31803 S32750 SS Plate from BAOSTEEL POSCO

Duplex stainless steels have a combination of two phases, ferrite and austenite in approximately equal measure. This allows them to benefit from the advantages of both austenitic and ferritic stainless steels, leading to increased strength, improved weldability, higher toughness and resistance to several types of corrosion. Commercially, they are also cheaper than austenitic stainless steels due to their lower nickel content.

Duplex stainless steel was developed in Sweden in 1930, but commercial production didn’t commence until the 1970s due to the very complicated process of its production. There has been a re-emergence in the steel in modern times after significant advances in steelmaking techniques have made it easier to produce it. However, they are still a relatively under-utilised group of stainless steels, with the world’s usage only between 1 – 3% due to the limitations of their application.

The properties of duplex stainless steel

The microstructure of duplex stainless steels features both the crystallographic structures of approximately 50% ferrite (a body-centred cubic structure) and 50% austenite (a face-centred cubic structure). Both of these phases co-exist as a stable mixture, unlike two-phase alloys, where one of the two phases manifests as precipitates. The alloying elements in duplex stainless steels are either ferritisers (e.g. chromium, silicon, molybdenum) or austenitisers (e.g. carbon, nickel, nitrogen), which means they favour the formation of the ferritic and austenitic phases, respectively.

At high temperatures, the relatively unstable ferrite phase in duplex steels gets converted into the undesirable α’ (alpha prime) phase, which causes a decrease in their mechanical properties, such as strength and toughness, and also in their corrosion resistance. This phenomenon is called embrittlement [1]. The worst temperature at which embrittlement occurs is at 475 oC; however, the production of the alpha prime phase may start to occur at temperatures as low as 300 oC, and this limits the maximum service temperature of duplex steels.

Typical duplex stainless steels show a higher yield strength than typical martensitic, austenitic and ferritic grades. However, they have a narrow range of working temperatures due to the precipitation of intermetallic phases that starts to occur above 300 oC and the onset of brittleness as they approach cryogenic temperatures [2]. The table below presents selected properties of some common grades of duplex stainless steels.

Duplex stainless steel grades and standards

In the early stages of the development of duplex stainless steels, there were only a few grades, the most popular one among them being duplex stainless steel UNS S31803. Thereafter, the development of new grades started, and they were determined by their end application, which can be categorised into two main types:

- Hyper-duplex and super-duplex stainless steels, which were created to operate in very corrosive environments but with less focus on their strength

- Lean and standard duplex stainless steels, which had more focus on increased strength and were to be used in mildly corrosive environments such as in structural applications.

These categories are now identified by the pitting resistance equivalence number (PREN) which is calculated by a formula based on the composition of duplex stainless steels.

PREN=%Cr+3.3×%Mo+16×%N

The table below shows the four sub-groups.

Table 2. Duplex stainless steel sub-groups

| Type |

Example grades |

Composition |

PREN |

| Cr% |

Ni% |

Mo% |

N% |

| Lean |

S31500, S32304, S32404 |

20-24 |

1-5 |

0.1-0.3 |

0.1-0.22 |

24-25 |

| Standard |

S31803, S32205 |

21-23 |

4.5-6 |

2.5-3.5 |

0.1-0.22 |

33-35 |

| Super-duplex |

S32520, S32550, S32750 |

24-29 |

4.5-8 |

2.7-4.5 |

0.1-0.35 |

>40 |

| Hyper-duplex |

S32707, S33207 |

27 |

6.5 |

5 |

0.4 |

49 |

Duplex stainless steel applications

Due to the limitations of duplex stainless steels such as poor formability and machinability, in addition to their highly complicated metallurgical process of production compared to ferritic, austenitic and martensitic stainless steels, duplex steels are used mostly for niche applications.

Applications of duplex stainless steels take into account their limitations and advantages, but the major applications require corrosion resistance, such as pitting and crevice corrosion resistance, stress corrosion resistance, fatigue corrosion, abrasion corrosion or resistance to corrosive environments that are acidic or caustic. Some of the common industrial applications are outlined below [4].

Duplex stainless steels are preferred to austenitic and ferritic stainless steels for the fabrication of vessels that contain bleach and other corrosive liquids in paper processing.

Desalination

Desalination of seawater, a process that presents highly corrosive chlorine in a high-temperature environment, is a sturdy test for a corrosion-resistant material. Duplex stainless steels have become the material of choice for the fabrication of evaporators. They can also be made with thinner cross-sections because of the higher strength and corrosion resistance of duplex stainless steels.

Oil and Gas

The development of duplex stainless steels with PRE numbers above 40 has made it possible to manufacture components such as pumps, piping and manifolds that require high resistance to pitting and crevice corrosion, which are crucial in the oil and gas industry.

Construction

Duplex stainless steels are used in the construction of load-bearing members that also require corrosion resistance. Typical applications include the construction of bridges over seawater or structures that are in close proximity to the sea.

Food and Drink Storage

Lean duplex steels show promise in the commercial storage of food and drinks during processing due to their relatively low cost while retaining excellent corrosion resistance and strength.

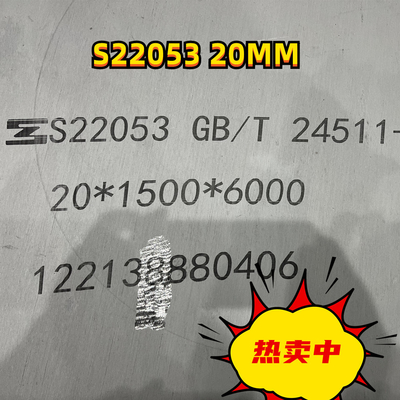

Stock informations of 2205 2507 Duplex stainless steel

| Thickness |

standard size 1000*2000mm |

standard size 1219*2438mm |

standard size 1500*6000mm |

standard size 2000*6000mm |

| 0.6mm |

● |

● |

|

|

| 0.8mm |

● |

● |

|

|

| 1.0mm |

● |

● |

● |

|

| 1.2mm |

● |

● |

● |

|

| 1.5mm |

● |

● |

● |

|

| 2.0mm |

● |

● |

● |

|

| 2.5mm |

● |

● |

● |

|

| 3.0mm |

● |

● |

● |

● |

| 4.0mm |

|

|

● |

● |

| 5.0mm |

|

|

● |

● |

| 6.0mm |

|

|

● |

● |

| 8.0mm |

|

|

● |

● |

| 10.0mm |

|

|

● |

● |

| 12.0mm |

|

|

● |

● |

| 14.0mm |

|

|

● |

● |

| 16.0mm |

|

|

● |

● |

| 20.0mm |

|

|

● |

● |

| 25.0mm |

|

|

● |

● |

| 30.0mm |

|

|

● |

● |

| 35.0mm |

|

|

● |

● |

| 40.0mm |

|

|

● |

● |

| 50.0mm |

|

|

● |

● |

| >50mm |

|

|

● |

|

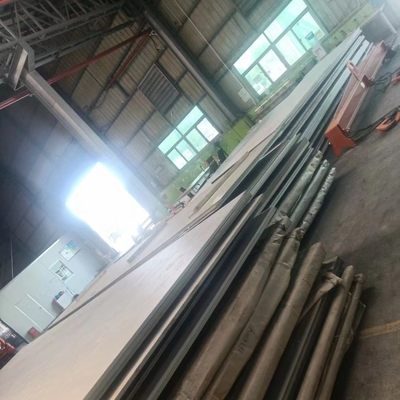

Products Show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!