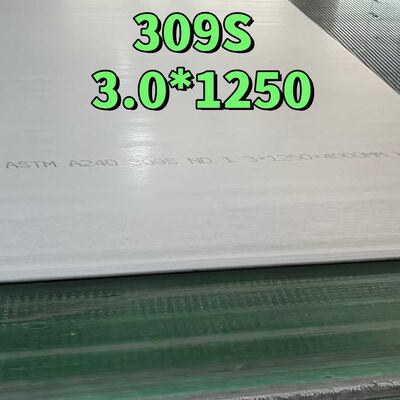

Hot Rolled ASTM A240 309S Stainless SteelPlates 3.0*1250*3000MM High Temperature Corrosion

General Properties

Alloy 309 (UNS S30900) is an austenitic stainless steel developed for use in high temperature corrosion resistance applications. The alloy resists oxidation up to 1900°F (1038°C) under non-cyclic conditions. Frequent thermal cycling reduces oxidation resistance to approximately 1850°F (1010°C).

Because of its high chromium and low nickel content, Alloy 309 can be utilized in sulfur containing atmospheres up to 1832°F (1000°C). The alloy is not recommended for use in highly carburizing atmospheres since it exhibits only moderate resistance to carbon absorption. Alloy 309 can be utilized in slightly oxidizing, nitriding, cementing and thermal cycling applications, albeit, the maximum service temperature must be reduced.

When heated between 1202 – 1742°F (650 – 950°C) the alloy is subject to sigma phase precipitation. A solution annealing treatment at 2012 – 2102°F (1100 – 1150°C) will restore a degree of toughness.

309S (UNS S30908) is the low carbon version of the alloy. It is utilized for ease of fabrication. 309H (UNS S30909) is a high carbon modification developed for enhanced creep resistance. It most instances the grain size and carbon content of the plate can meet both the 309S and 309H requirements.

Alloy 309 can be easily welded and processed by standard shop fabrication practices.

Applications

- Furnaces — burners, doors, fans, piping and recuperators

- Fluidized Bed Furnaces — grids, piping, wind boxes

- Paper Mill Equipment

- Petroleum Refining — catalytic recovery systems, recuperators

- Power Generation — pulverized coal burners, tube hangers

- Thermal Processing — annealing covers and boxes, burners grids, doors, fans, lead pans and neutral salt pots, muffles and retorts, recuperators, walking beams

- Waste Treatment — incinerators, rotary kilns and calciners

Standards

ASTM........A 240

ASME........SA 240

AMS..........5523

Corrosion Resistance

Wet Corrosion

Alloy 309 is not designed for service in wet corrosive environments. The high carbon content, which is present to enhance creep properties, has a detrimental effect on aqueous corrosion resistance. The alloy is prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (23%), Alloy 309 is more corrosion resistant than most heat resistant alloys.

High Temperature Corrosion

Alloy 309 resists high temperature corrosion in most in-service conditions. Operating temperatures are as follows:

Oxidizing conditions (max. sulfur content – 2 g/m3)

1922°F (1050°C) continuous service

2012°F (1100°C) peak temperature

Oxidizing conditions (max. sulfur greater than 2 g/m3)

1742°F (950°C) maximum temperature

Low oxygen atmosphere (max. sulfur content – 2 g/m3)

1832°F (1000°C) maximum temperature

Nitriding or carburizing atmospheres

1562 –1742°F (850 – 950°C) maximum

The alloy does not perform as well as Alloy 600 (UNS N06600) or Alloy 800 (UNS N08800) in reducing, nitriding or carburizing atmospheres, but it does outperform most heat resistant stainless steels in these conditions.

Creep Properties

Typical Creep Properties

| Temperature |

Creep Strain (MPa) |

Creep Rapture (MPa) |

| °C |

°F |

1000 H |

10000 H |

100000 H |

1000 H |

10000 H |

100000 H |

| 600 |

1112 |

120 |

80 |

40 |

190 |

120 |

65 |

| 700 |

1292 |

50 |

25 |

20 |

75 |

36 |

16 |

| 800 |

1472 |

20 |

10 |

8 |

35 |

18 |

7.5 |

| 900 |

1652 |

8 |

4 |

3 |

15 |

8.5 |

3 |

| 1000 |

1832 |

4 |

2.5 |

1.5 |

8 |

4 |

1.5 |

Chemical Analysis

Weight % (all values are maximum unless a range is otherwise indicated)

| Element |

309 |

309S |

309H |

| Chromium |

22.0 min.-24.0 max. |

22.0 min.-24.0 max. |

22.0 min.-24.0 max. |

| Nickel |

12.0 min.-15.0 max. |

12.0 min.-15.0 max. |

12.0 min.-15.0 max. |

| Carbon |

0.20 |

0.08 |

0.04 min.-0.10 max. |

| Manganese |

2.00 |

2.00 |

2.00 |

| Phosphorus |

0.045 |

0.045 |

0.045 |

| Sulfer |

0.030 |

0.030 |

0.030 |

| Silicon |

0.75 |

0.75 |

0.75 |

| Iron |

Balance |

Balance |

Balance |

Physical Properties

Density

0.285 lbs/in3

7.89 g/cm3

Specific Heat

0.12 BTU/lb-°F (32 – 212°F)

502 J/kg-°K (0 – 100°C)

Modulus of Elasticity

28.5 x 106 psi

193 GPa

Thermal Conductivity 212°F (100°C)

9.0 BTU/hr/ft2/ft/°F

15.6 W/m-°K

Melting Range

2500 – 2590°F

1480 – 1530°C

Electrical Resistivity

30.7 Microhm-in at 68°C

78 Microhm-cm at 20°C

Mechanical Properties

Typical Values at 68°F (20°C)

Yield Strength

0.2% Offset |

Ultimate Tensile

Strength |

Elongation

in 2 in. |

Hardness |

| psi (min.) |

(MPa) |

psi (min.) |

(MPa) |

% (min.) |

(max.) |

| 45,000 |

310 |

85,000 |

586 |

50 |

202 (HBN) |

Fabrication Data

Alloy 309 can be easily welded and processed by standard shop fabrication practices.

Hot Forming

Heat uniformly at 1742 – 2192°F (950 – 1200°C). After hot forming a final anneal at 1832 – 2101°F (1000 – 1150°C) followed by rapid quenching is recommended.

Cold Forming

The alloy is quite ductile and forms in a manner very similar to 316. Cold forming of pieces with long-term exposure to high temperatures is not recommended since the alloy is subject to carbide precipitation and sigma phase precipitants.

Welding

Alloy 309 can be readily welded by most standard processes including TIG, PLASMA, MIG, SMAW, SAW and FCAW.

Q1: What products can you offer?

A: We can offer you general steel types like 310S, 316L,304.304L.201,904L, 316H, 316,316L 300and 400 series, and duplex stainless steel like 2205, 2304,2101,2507,etc. 904L, 800H, 600H high-nickel alloy.

Q2. Can you produce the products according to my own drawings?

A: Yes, we can produce the products according to your drawings that will be most satisfy you.

Q3. How does your factory do regarding quality control?

A: Quality is the priority. We always attach great importance to quality controlling from the beginning to end.

Q4. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request,

but you have to bear their own costs incurred during this period and the spreads.

Q5: How long is the delivery time?

A: 3~30working days after confirming the payment.

If the order is urgent, we will push our workshop finish in advance.

Q6: What is your Payment?

A: T/T, L/C, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!