16-300 mm 60Si2MnA Quality Round Bar High Carbon Spring Steel JIS SUP7 | DIN 60Si7 | ASTM 9260 Rod

MITTEL ship out steel round bar and plate to many different counties every month, such as Malaysia, Singapro, Vietnam, India, Korea, Indonesia, Australia, Ireland, Italy, Greece, Israel, Dubai, Saudi Arabia, Mexco, Colombia, Argentina, Peru, South Africa...

1: Main Product:

GB

GB/T 1299 |

JIS

JIS G4404 |

DIN (W-Nr.)

DIN EN ISO4957 |

AISI/ASTM

ASTM A681 |

BS

BS 4659 |

| Cold Work Tool Steel |

| Cr12 |

SKD1 |

1.2080/X210Cr12 |

D3 |

|

| Cr5Mo1V |

SKD12 |

1.2363/X100CrMoV5 |

A2/T30102 |

BA2 |

| Cr12MoV |

|

1.2601 |

D5 |

|

| Cr12Mo1V1 |

SKD11 |

1.2379/X153CrMo12 |

D2 |

|

| X210CrW12 |

SKD2 |

1.2436 |

D6 |

|

| 9CrWMn |

SKS3 |

1.2510/100MnCrW4 |

O1 |

|

| 9Mn2V |

|

1.2842 / 90MnCrV8 |

O2 |

B02 |

| 5CrNiMo |

SKT4 |

1.2713 |

L6/T61206 |

BH224/5 |

| Hot work Tool Steel |

| |

|

1.2355/50CrMoV13-15 |

S7/T41907 |

|

| 5CrNiMoV |

|

1.2714 |

6F3 |

|

| 5CrNi4Mo |

|

1.2767 |

6F7 |

|

| |

SKD7 |

1.2365/32CrMoV12-28 |

H10/T20810 |

BH10 |

| 4Cr5MoV |

SKD6 |

1.2343/X37CrMoV5-1 |

H11/T20811 |

BH11 |

| 4Cr5MoSiV1 |

SKD61 |

1.2344/X40CrMoV5-1 |

H13 |

|

| |

SKD62 |

1.2605/X35CrWMoV5 |

H12/T20812 |

BH12 |

| 3Cr2W8V |

SKD5 |

1.2581 |

H21 |

|

| Plastic Mould Steel |

| 3Cr2Mo |

|

1.2311 |

P20 |

|

| |

NAK80 |

1.2312 |

P20+S / P21 |

|

| 3Cr2MnNiMo |

|

1.2738 |

P20+Ni / 718 |

|

| 4Cr13 |

SUS420J2 |

1.2083 |

415 |

|

| 3Cr17+S |

SUS420F |

1.2085 |

|

|

| 3Cr17Mo |

SUS420J |

1.2316 |

|

|

| Engineering Steel |

GB

GB/T 699 |

JIS

JIS G4051 |

DIN (W-Nr.)

EN 10083-2 |

AISI/ASTM

ASTM A20 |

EN / BS |

| |

|

|

1018 |

EN2C |

| 20 |

S20C |

C20/1.1151 |

1020 |

EN3B /070M20 |

| |

S35C |

C35 |

1035 |

|

| |

|

|

1040 |

EN8/080M40 |

| 45 |

S45C |

C45/1.1191 |

1045 |

EN8D/C45E |

| 50 |

S50C |

|

1050 |

|

| |

S55C |

|

1055 |

EN9/070M55 |

| Q345 |

|

S355/ST52-3/1.1170 |

|

EN14/150M19 |

GB

GB/T 3077 |

JIS

JIS G4105/JIS G4103 |

DIN (W-Nr.)

EN 10250 |

AISI/ASTM

ASTM A29 |

BS

BS 970 |

| 40Cr |

SCr440 |

41Cr4(1.7035) |

5140 |

|

| |

SCM420 |

18CrMo4/1.7243 |

4118 |

|

| 30CrMo |

SCM430 |

25CrMo4/1.7218 |

4130 |

708A25/708M25 |

| 42CrMo |

SCM440 |

42crmo4/1.7225 |

4140 |

EN19/709M40 |

| |

|

|

4145 |

|

| |

|

|

4330 |

|

| 40CrNiMoA |

SNCM 439/SNCM8 |

36CrNiMo4/1.6511 |

4340 |

EN24/817M40 |

| |

|

40NiMoCr10-5/1.6745 |

|

EN26 |

| |

|

34CrNiMo6 / 1.6582 |

4337 |

|

| |

|

30CrNiMo16-6/1.6747 |

|

EN30B/835M30 |

| |

|

32CrMo12/1.7361 |

|

EN40B/722M24 |

| |

SCM415 |

16MnCr5 / 1.7131 |

5115 |

|

| |

|

15CrNi6/1.5919 |

3115 |

|

| |

|

16NiCr4/1.5714 |

|

EN351/635M15 |

| |

|

|

4615/4617 |

EN34/665M17 |

| |

|

14NiCr4/1.5752 |

3310/3415 |

EN36/655M13 |

| |

|

15NiCrMo16-5/1.6723 |

|

EN39/835M15 |

| |

|

18CrNiMo7-6 (1.6587) |

4815 |

|

| |

SNCM220 |

1.6523/21NiCrMo2 |

8620 |

805M20 |

| |

|

20CrNiMo5 |

|

EN353 |

| GCr15 |

|

52100/1.3505 |

|

EN31/535A99 |

| Stainless Steel |

| |

SUS440C |

X105CrMo17/1.4125 |

S44004/440C |

|

| Wear-resisting Steel |

| GB |

JIS |

DIN (W-Nr.) |

AISI/ASTM |

SSAB |

| NM400 |

|

HB400 |

|

|

| NM500 |

|

HB500 |

|

|

| Spring Steel |

| GB |

JIS |

DIN (W-Nr.) |

AISI/ASTM |

SSAB |

| 65MN |

|

|

1066 |

|

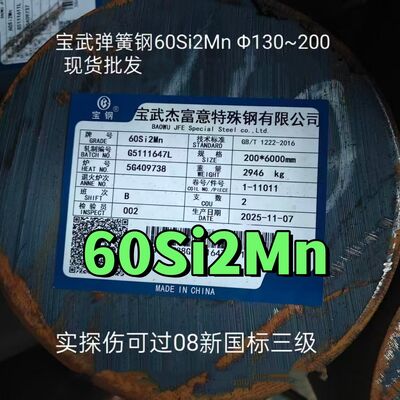

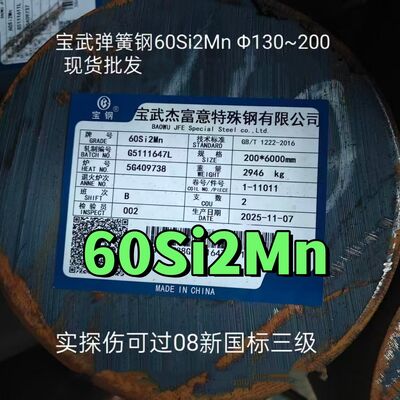

| 60Si2Mn |

SUP6 |

60Si7 |

9260 |

|

| 60Si2MnA |

SUP7 |

60Si7 |

9260 |

|

| 55CrMnA |

SUP9 |

55Cr3 |

5155 |

|

| 60CrMnA |

SUP9A |

|

5160 |

|

| 50CrVA |

SUP10 |

51CrV4 |

6150 |

|

| High Speed Steel |

| GB |

JIS

JIS G4403 |

DIN (W-Nr.)

DIN EN ISO 4957 |

AISI/ASTM

ASTM A600 |

BS

BS 4659 |

| |

SKH51 |

1.3343 |

M2 |

|

| |

SKH55 |

1.3243/HS6-5-2-5 |

M35 |

|

| |

SKH59 |

1.3247/HS2-9-1-8 |

M42 |

|

| |

SKH2 |

HS18-0-1/1.3355 |

T1 |

|

| |

SKH3 |

S 18-1-2-5/1.3255 |

T4/T12004 |

|

| |

SKH4 |

1.3265/S18-1-2-10 |

T5/T12005 |

BT5 |

| All kinds of forging parts according to Drawing |

2: Qilu steel overviews

| Size |

Round |

Dia 8-1200mm |

| Plate/Flat/Block |

Thickness

10mm-800mm |

Width

20mm-2000mm |

| Heat treatment |

Normalized ; Annealed ; Quenched ; Tempered |

| Surface condition |

Black; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Delivery condition |

Forged; Hot rolled; Cold drawn |

| Test |

Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. |

| Payment terms |

T/T;L/C;/Money gram/ Paypal |

| Trade terms |

FOB; CIF; C&F; etc.. |

| Delivery time |

30-45 days

|

Quick Details

1: SUP7 steel introduction

JIS SUP7 Steel is a high quality Alloy Spring Steel, It belong to the high quality high carbon alloy Spring Steel. Quenched & Tempered Hardness is 28-34 HRc. SUP7 steel Annealing delivery hardenss less than 250HB.

.

2: SUP7 Steel equivalent

| Country |

Japan |

BS |

China |

USA |

| Standard |

JIS G4801 |

EN 10089 |

GB/T 1222 |

ASTM A29 |

| Grade |

SUP7 |

60Si7 |

60Si2MnA |

9260 |

3: SUP7 steel chemical composition

| Grade |

C |

Si |

Mn |

P |

S |

Cr |

V |

Ni |

| 9260 |

0.56-0.64 |

1.8-2.2 |

0.75-1.0 |

0.035 |

0.040 |

/ |

/ |

/ |

| 60Si7 |

0.56-0.64 |

1.6-2.0 |

0.6-0.9 |

0.025 |

0.025 |

/ |

/ |

/ |

| SUP7 |

0.56-0.64 |

1.8-2.2 |

0.7-1.0 |

0.030 |

0.030 |

/ |

/ |

/ |

| 60Si2MnA |

0.56-0.64 |

1.6-2.0 |

0.7-1.0 |

0.025 |

0.020 |

0.35 |

/ |

/ |

4: SUP7 steel mechanical properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5: SUP7 steel overviews

| Size |

Round |

Dia 6-120mm |

| Plate/Flat/Block |

Thickness

6mm-60mm |

Width

20mm-160mm |

| Heat treatment |

Normalized ; Annealed ; Quenched ; Tempered |

| Surface condition |

Black; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Delivery condition |

Forged; Hot rolled; Cold drawn |

| Test |

Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. |

| Payment terms |

T/T;L/C;/Money gram/ Paypal |

| Trade terms |

FOB; CIF; C&F; etc.. |

| Delivery time |

30-45 days |

| Application |

automobile, locomotive, large plate spring, spring, etc. SUP7 Spring main used for heavy vehicles, tractors, industrial production load, stress and the diameter of the larger plate spring and helical spring. |

6: Delivery condition

For hot rolled bar, usually the delivery condition is hot rolled, annealed, Black surface.

For hot rolled sheet, usually the delivery conditon is hot rolled, annealed, black surface.

1. who are we?

We are based in Jiangsu, China, start from 2022,sell to Africa(28.00%),South America(25.00%),Southeast Asia(16.00%),South Asia(15.00%),Oceania(4.00%),Mid East(3.70%),North America(3.00%),Eastern Europe(2.00%),Eastern Asia(1.20%),Northern Europe(1.00%),Central America(0.60%),Domestic Market(0.50%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

steel Round Bar stainless Steel coil,Alumium coil,copper coil,brass coil,lead sheet

4. why should you buy from us not from other suppliers?

Our company have established a first-class marketing team with first-class efficiency and first-class service! With high-quality products, strive to meet the various requirements of customers.

5. what services can we provide?

Accepted Payment Currency:USD;

Accepted Payment Type: T/T;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!