Cold Rolled Steel Sheet Quality Standard SAE 1020 20# Thickness 2.5 mm 1250*2500mm

SAE AISI 1045 Steel

ASTM SAE AISI 1045 steel is one of the commonly used medium carbon steels with an average carbon content of 0.45%, medium tensile properties, good strength, toughness and wear resistance. It can be treated by annealing, flame treatment or induction hardening.

C1045 is also known as 1045 cold rolled steel (cold worked), and 1045 hot rolled steel is known as 1045 HR.

Applications

AISI SAE 1045 material is widely used in industrial applications where higher wear resistance and strength are required, typical applications including: Light gears, shafts, axles, spindles, pins, guide rods, connecting rods, bolts, worms, crankshafts, machine components, etc.

Datasheet & Specification

The table below gives the AISI SAE ASTM 1045 steel data sheet including chemical composition, physical properties, mechanical properties, etc.

Chemical Composition

| |

AISI ASTM 1045 Chemical Composition (%) |

| Steel Grade (UNS) |

C |

Mn |

P (≤) |

S (≤) |

| 1045 (G10450) |

0.43-0.50 |

0.60-0.90 |

0.040 |

0.050 |

Physical Properties

| AISI SAE 1045 coefficients of linear thermal expansion |

| Value (10-6/K) |

Temperature (°C) |

Treatment

or condition |

| 11.6 |

0-100 |

Annealed |

| 12.3 |

0-200 |

| 13.1 |

0-300 |

| 13.7 |

0-400 |

| 14.2 |

0-500 |

| 14.7 |

0-600 |

| 15.1 |

0-700 |

| Material 1045 thermal conductivity |

| Value (W/m·K) |

Temperature (°C) |

Treatment

or condition |

| 50.8 |

100 |

Annealed |

| Material 1045 thermal conductivity |

| Value (W/m·K) |

Temperature (°C) |

Treatment

or condition |

| 50.8 |

100 |

Annealed |

| Electrical Resistivity of AISI SAE 1045 Carbon Steel |

| Value (μΩ·m) |

Temperature (°C) |

Treatment

or condition |

| 0.162 |

20 |

Annealed |

| 0.223 |

100 |

Mechanical Properties

1045 material mechanical properties are listed in the following table including tensile strength, yield strength, elongation, reduction and hardness, etc.

| |

1045 carbon steel mechanical properties (sizes ranging: 19-32 mm) |

| Steel (UNS) |

Tensile strength (Mpa) ≥ |

Yield strength (Mpa) ≥ |

Elongation in 50 mm, % ≥ |

Reduction in area, % ≥ |

Hardness (HB) |

Processing, condition or treatment |

| AISI SAE 1045 (G10450) |

565 |

310 |

16 |

40 |

163 |

Hot rolled |

| 625 |

530 |

12 |

35 |

179 |

Cold drawn |

| 585 |

505 |

12 |

45 |

170 |

Annealed, cold drawn |

1045 Steel Heat Treatment

Normalizing

1045 normalizing temperature range is 830-900 °C and the typical normalizing temperature is 860 °C.

Austenitizing

The austenitizing temperature for SAE 1045 induction hardening carbon steel is 800-845 °C.

Full Annealing

The annealing temperature for AISI 1045 carbon steel is from 790-870 °C, cooling cycle from 790 to 650 °C at a rate of 28 °C/h in furnace, and can get the HBW hardness range from 156 to 217. (Suitable for forgings with a section thickness of up to 75 mm. For the section up to 25 mm thick, the temperature time is usually at least 1 hour; for each 25 mm thick increase, 0.5 h is added.)

Hardening

The austenitizing heating at 845 °C, the quenching medium is water or brine, and the workpiece with wall thickness ≤6.35 mm is oil quenched, and the hardness should be no less than 55 HRC.

Welding

For the thickness of the weldment is ≤13mm, the preheating and interpass temperature is at least 150 °C under low hydrogen condition, other than low hydrogen, the temperature is minimum 177 °C, heat treatment is required after welding and the temperature range is 590-675 °C.

For the weldment thickness (t) 13<t≤100mm, the preheating and interpass temperature is ≥205 °C (under low hydrogen condition), ≥230 °C (except low hydrogen), and the postweld heat treatment temperature is 590-675 °C.

1045 Steel Equivalent Grade

ASTM AISI SAE 1045 carbon steel equivalent to European EN (Germany DIN EN, British BSI, French NF…), Chinese GB and Japanese JIS standard.

| AISI 1045 equivalent |

| US |

Germany |

China |

Japan |

ISO |

| Standard |

Grade (UNS) |

Standard |

Steel name (Steel number) |

Standard |

Grade |

Standard |

Grade |

Standard |

Grade |

AISI

SAE;

ASTM A29/A29M |

1045 (G10450) |

EN 10083-2 |

C45 (1.0503) |

GB/T 699 |

45 Steel |

JIS G 4051 |

S45C |

Our Advantages

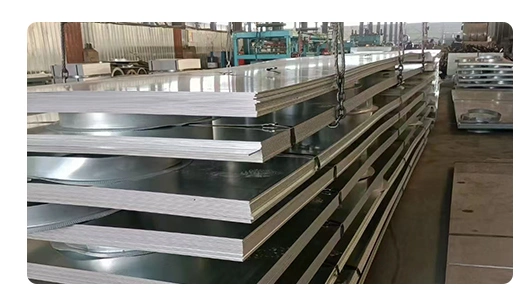

High precision

Cold-rolled high-quality thin steel plate: mainly includes various high-quality steel cold-rolled thin plates, the most commonly used is carbon structural steel plate, especially cold-rolled thin steel plate for deep drawing, which is cold-rolled thin plate made of low-carbon high-quality steel 08Al. The quality is divided into three groups;1 ,2 and 3, which represent particularly high-grade, high-grade, and higher-finish surfaces, respectively.

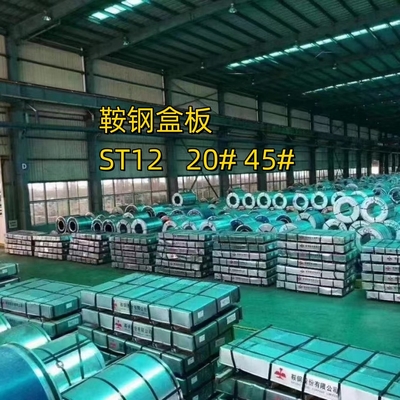

Extensive use

Cold-rolled steel plate with smooth surface and excellent processing, used for home appliances such as automobiles, refrigerators, washing machines, industrial equipment, and various building materials. With the development of the economy, cold-rolled steel sheets have been called necessary materials in modern society. Classification of cold-rolled products: hot-rolled pickling, hard-rolled coil, ordinary cold-rolled, galvanized (electro-galvanized, anti-fingerprint, hot-dip galvanized), galvanized, electro-tinned, color-coated, electrical steel (silicon steel sheet) wait.

Strict craftsmanship

Cold rolled steel coils generally use hot-rolled strip steel with a thickness of 1.5-6 mm as the cold rolled billet. The main processes include pickling, cold rolling, degreasing, annealing, leveling, and shearing (cross cutting, longitudinal cutting). If producing coated plates, there are also plating or coating processes such as electroplating tin, hot tin coating, and hot zinc coating. The production process of cold rolled billets is as follows: hot rolled sheet coils (raw materials) - acid washing - cold rolling - degreasing - annealing - leveling - shearing - finished product delivery.

Provide deep processing

The company's slitting machine, slitting line, cuts cold rolled steel coils into strips of various widths as needed, and then folds the strips into small coils for use in the next process. It is a necessary equipment for precision cutting of transformers, motor industries, and other metal strips. It is mainly used for strip cutting of materials such as tinplate, galvanized iron, silicon steel sheet, cold rolled strip, stainless steel strip, aluminum strip, steel strip, and other coils.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!