Type Analysis

| Element |

Min |

Max |

| Carbon |

0.05 |

0.15 |

| Manganese |

0.30 |

1.00 |

| Silicon |

0.25 |

0.75 |

| Phosphorus |

-- |

0.03 |

| Sulfur |

-- |

0.015 |

| Chromium |

20.00 |

24.00 |

| Cobalt |

-- |

5.00 |

| Iron |

-- |

3.00 |

| Aluminum |

0.20 |

0.50 |

| Titanium |

-- |

0.10 |

| Boron |

-- |

0.015 |

| Copper |

-- |

0.50 |

| Lanthanum |

0.005 |

0.05 |

| Tungsten |

13.00 |

15.00 |

| Molybdenum |

1.00 |

3.00 |

| Nickel |

REM |

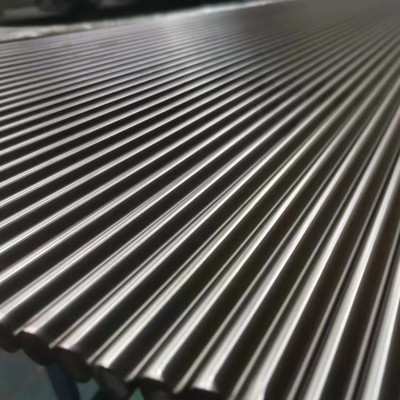

Principal Features

Excellent High-Temperature Strength, Thermal Stability, and Environment Resistance

Haynes 230 alloy is a nickel-chromium-tungsten-molybdenum alloy that combines excellent high temperature strength, outstanding resistance to oxidizing environments up to 2100°F (1149°C) for prolonged exposures, premier resistance to nitriding environments, and excellent long-term thermal stability. It is readily fabricated and formed, and is castable. Other attractive features include lower thermal expansion characteristics than most high-temperature alloys, and a pronounced resistance to grain coarsening with prolonged exposure to high-temperatures.

Easily Fabricated

Haynes 230 alloy has excellent forming and welding characteristics. It may be forged or otherwise hot-worked, providing that it is held at 2150°F (1177°C) for a time sufficient to bring the entire piece to temperature. As a consequence of its good ductility, 230 alloy is also readily formed by cold-working. All hot- or cold-working parts should be annealed and rapidly cooled in order to restore the best balance of properties. The alloy can be welded by a variety of techniques, including gas tungsten arc (GTAW), gas metal arc (GMAW), and resistance welding.

Heat-Treatment

Wrough 230 alloy is furnished in the solution heat-treated condition, unless otherwise specified. The alloy is solution heat-treated in the range of 2150 to 2275°F (1177°C) and rapidly cooled or water-quenched for optinum properties.

Annealing at temperatures lower than the solution heat-treating temperatures will produce some carbide precipitation in 230 alloy, which may marginally affect the alloy's strength and ductility.

Casting

Haynes 230 alloy may be cast using traditional air-melt sand mold or vacuum-melt investment casting foundry practices. Silicon levels at the high end of the specification range are recommended for enhanced fluidity. Castings may be used in either the as-cast or solution-heat-treated condition depending upon property requirements.

Applications

Haynes 230 alloy combines properties which make it ideally suited for a wide variety of component applications in the aerospace and power industries. It is used for combustion cans, transition ducts, flameholders, thermocouple sheaths, and other important gas turbine components. In the chemical process industry, 230 alloy is used for catalyst grid supports in ammonia burners, high-strength thermocouple protection tubes, high-temperature heat exchangers, ducts, high-temperature bellows, and various other key process internals.

In the industrial heating industry, applications for 230 alloy include furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals, and many more.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!