Duplex 2205 stainless steel (both ferritic and austenitic) is used extensively in applications that require good corrosion resistance and strength. The S31803 grade stainless steel has undergone a number of modifications resulting in UNS S32205, and was endorsed in the year 1996. This grade offers higher resistance to corrosion.

At temperatures above 300°C, the brittle micro-constituents of this grade undergo precipitation, and at temperatures below -50°C the micro-constituents undergo ductile-to-brittle transition; hence this grade of stainless steel is not suitable for use at these temperatures.

Key Properties

The properties that are mentioned in the below tables pertain to flat rolled products such as plates, sheets and coils of the ASTM A240 or A240M. These may not be uniform across other products such as bars and pipes.

Composition

Composition ranges for 2205 grade stainless steels

| Grade |

|

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

| 2205 (S31803) |

Min

Max

|

-

0.030

|

-

2.00

|

-

1.00

|

-

0.030

|

-

0.020

|

21.0

23.0

|

2.5

3.5

|

4.5

6.5

|

0.08

0.20

|

| 2205 (S32205) |

Min

Max

|

-

0.030

|

-

2.00

|

-

1.00

|

-

0.030

|

-

0.020

|

22.0

23.0

|

3.0

3.5

|

4.5

6.5

|

0.14

0.20

|

Mechanical Properties

Mechanical properties of 2205 grade stainless steels

| Grade |

Tensile Str

(MPa) min |

Yield Strength

0.2% Proof

(MPa) min |

Elongation

(% in 50mm) min |

Hardness |

| Rockwell C (HR C) |

Brinell (HB) |

| 2205 |

621 |

448 |

25 |

31 max |

293 max |

Physical properties of 2205 grade stainless steels

| Grade |

Density

(kg/m3) |

Elastic

Modulus

(GPa)

|

Mean Co-eff of Thermal

Expansion (μm/m/°C) |

Thermal

Conductivity (W/m.K) |

Specific

Heat

0-100°C

( J/kg.K)

|

Electrical

Resistivity

(nΩ.m) |

| 0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

| 2205 |

7800 |

190 |

13.7 |

14.2 |

- |

19 |

- |

418 |

850 |

Grade Specification Comparison

Grade specification comparisons for 2205 grade stainless steels

| Grade |

UNS

No |

Old British |

Euronorm |

Swedish

SS

|

Japanese

JIS

|

| BS |

En |

No |

Name |

| 2205 |

S31803 / S32205 |

318S13 |

- |

1.4462 |

X2CrNiMoN22-5-3 |

2377 |

SUS 329J3L |

Grade specification comparisons for 2205 grade stainless steels

| Grade |

Reasons for choosing the grade |

| 904L |

Better formability is needed, with similar corrosion resistance and lower strength. |

| UR52N+ |

High resistance to corrosion is required, e.g. resistance to higher temperature seawater. |

| 6%Mo |

Higher corrosion resistance is required, but with lower strength and better formability. |

| 316L |

The high corrosion resistance and strength of 2205 are not needed. 316L is lower cost. |

Heat ResistanceGrade 2205 stainless steel exhibits excellent corrosion resistance, much higher than that of grade 316. It resists localized corrosion types like intergranular, crevice and pitting. The CPT of this type of stainless steel is around 35°C. This grade is resistant to chloride stress corrosion cracking (SCC) at temperatures of 150°C. Grade 2205 stainless steels are apt replacements to austenitic grades, especially in premature failure environments and marine environments.

The high oxidation resistance property of Grade 2205 is marred by its embrittlement above 300°C. This embrittlement can be modified by a full solution annealing treatment. This grade performs well at temperatures below 300°C.

Heat Treatment

The best suited heat treatment for this grade is solution treatment (annealing), between 1020 - 1100°C, followed by rapid cooling. Grade 2205 can be work hardened but cannot be hardened by thermal methods.

Welding

Most standard welding methods suit this grade, except welding without filler metals, which results in excess ferrite. AS 1554.6 pre-qualifies welding for 2205 with 2209 rods or electrodes so that the deposited metal has the right balanced duplex structure.

Adding nitrogen to the shielding gas ensures that adequate austenite is added to the structure. The heat input must be maintained at a low level, and the use of pre or post heat must be avoided. The co-efficient of thermal expansion for this grade is low; hence the distortion and stresses are lesser than that in austenite grades.

Machining

The machinability of this grade is low due to its high strength. The cutting speeds are almost 20% lower than that of grade 304.

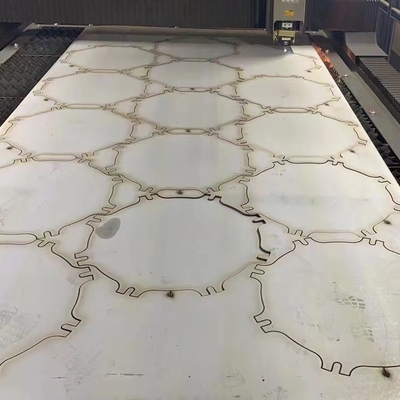

Fabrication

The fabrication of this grade is also affected by its strength. Bending and forming of this grade requires equipment with larger capacity. Ductility of grade 2205 is lesser than austenitic grades; therefore, cold heading is not possible on this grade. In order to carry out cold heading operations on this grade, intermediate annealing should be carried out.

Applications

Some of the typical applications of duplex steel grade 2205 are listed below:

- Oil and gas exploration

- Processing equipment

- Transport, storage and chemical processing

- High chloride and marine environments

- Paper machines, liquor tanks, pulp and paper digesters

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!