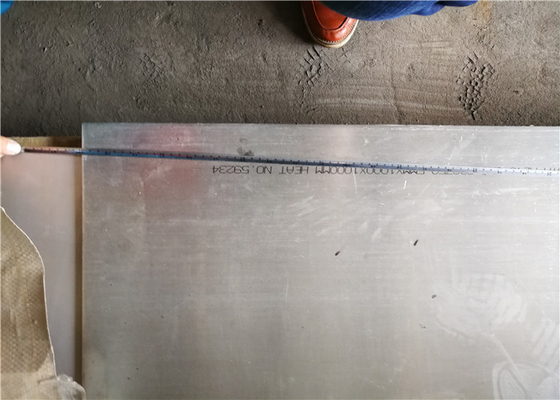

Hastelloy C276 Plate/Sheet (N10276/ NS334/333 W.Nr.2.4819) 0.4-10mm thickness

Chemical composition:

Nickel............................................................................................Balance

Molybdenum ................................................................................15.0-17.0

Chromium.....................................................................................14.5-16.5

Iron ..............................................................................................4.0-7.0

Tungsten......................................................................................3.0-4.5

Cobalt ..........................................................................................2.5 max.

Manganese ..................................................................................1.0 max.

Carbon.........................................................................................0.01 max.

Vanadium.....................................................................................0.35 max.

Phosphorus .................................................................................0.04 max.

Sulfur ...........................................................................................0.03 max.

Silicon ..........................................................................................0.08 max

Characteristic as below:

Alloy c-276 is a nickel-chromium-molybdenum alloy containing tungsten and extremely low carbon and

silicon contents.

Alloy c-276 is characterised by:

1.excellent resistance to a wide range of corrosive media,under oxidizing and reducing conditions

2.excellent resistance to pitting, crevice corrosion,

Corrosion resistance:

Alloy c-276 can be used in many chemical processes with oxidizing and with reducing media.Its corrosion resistance in lightly aerated, technical grade sulphuric acid is shown in Fig. 2. Except for areas where acorrosion rate of > 0.5 mm/a is indicated the use of Alloy c-276 is considered suitable.

The high molybdenum and chromium contents render the alloy resistant to chloride ion attack. The tungsten content further increases this resistance.

Alloy c-276 is one of the few materials that is resistant to moist chlorine gas, hypochlorite and chlorine

dioxide solutions. The alloy exhibits excellent resistance to concentrated solutions of oxidizing salts(such as iron (III) chloride and copper chloride)

Application range and field:

1.Pulp and paper industry, e.g. for digestion and bleaching vessels

2.Scrubbers and special reheaters as well as wet-operating

3.fans for combustion and flue gas desulphurisation systems

4.Equipment and components for sour-gas service

5.Reactors for acetic acid production

6.Sulphuric acid coolers

7.Methylene diphenyl isocyanate (MDI)

8.Manufacture and processing of technically impure phosphoric acid

9.Combustion-resistant alloy for high pressure oxygen

The reason why you choose us

1. Small quantity, short time delivery

If we have stocks, we can ship from a minimum of 1 kg sample in a few days.

We also manufacture custom-order materials in amounts of 300 kg and up

(Some materials are allowed 50 kg) in as few as 3 weeks.

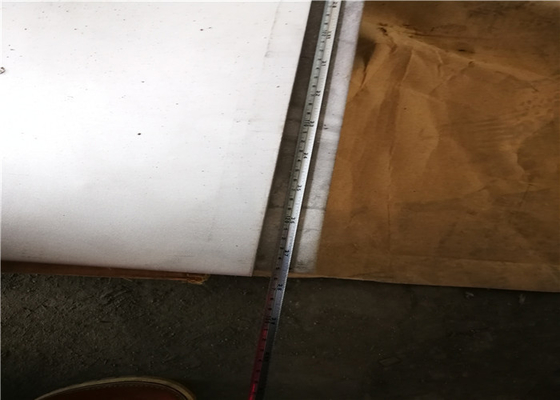

2. High-precision thickness

We guarantee thickness tolerances that cannot be reproduced by competitors.

Example:

t <0.30mm Tolerance ±1 - 3 μm guaranteed

0.30 mm≤t Tolerance ± 1% guaranteed

3. Ability to add multiple features

We are capable of adding a variety of features to metallic materials

(resin coating, plating, bonding different kinds of metal, multigage skiving, etc.).

4. Unique technology and custom-made solutions

We provide customed solutions to your problems with our unique

technologies and well versed knowledge of materials acquired through

our experience of manufacturing 50,000 items.

5. Choose the appropriate base metals for your needs

We carefully balance quality, delivery time and price,

procure various base metals from all over the world.

We manufacture appropriate products to your needs.

6. To control metal structure(chemical formation)

We can manufacture ultrafine metal structures with a grain size of 1 μm.

Using finer grain sizes provides benefits such as hardenability,

balancing strength and ductility, and precision press processing.

7. Lower total cost

We taking your processing into account,

offer you reduce a total cost by using our product.

8. Global network

Our plant located in Japan, Shanghai and Taiwan,

we also support flexibly local procurement and production transfer.

contact me

FAQ

How can I contact with your company?

We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile

telephone.

Mobile: +86-13812005384 Skype:karen@stainlesssteel-sheetmetal.comWhatsapp: +86-13812005384

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

If you have any questions,please contact me at any time!!!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!